During the summer of 2018, SUEZ-Toms River tasked the Kiely Family of Companies with designing and building an elevated walkway between two aerators located at their Toms River Holly Water Treatment Plant facility to increase efficiency and safety at the plant.

Our teams were asked to develop an interconnecting platform between the aerators to eliminate the current repetitive process that required operators to climb up and down one aerator at a time. With authorization to proceed in October 2018, our experienced teams moved forward with the design-build project to be completed before year’s-end.

Challenges

- Design a safe, OSHA compliant, economical support system for a bridge between the two existing elevated aerators.

- Provide integration between the new structural steel support and the existing catwalk system surrounding the aerators.

- Construct a bridge within a tight area in regards to the design specification and SUEZ’s daily operations.

Solution

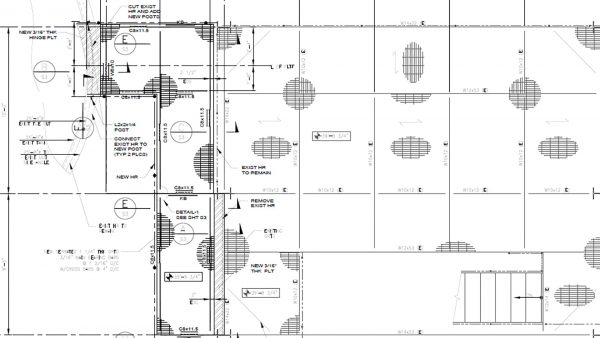

The Kiely Family of Companies structural engineering team inspected the as-built conditions at the site, in addition to the available record drawings supplied by SUEZ, to produce an individualized water resources design with all proposed requirements, as seen in the drawing below.

At this point, our design and construction teams were able to collaborate to provide an evaluation of the proposed plan and to develop an efficient construction procedure to complete this project on time, on budget, and on expectation.

The Kiely Family of Companies proposed a design-build solution that provided SUEZ with minimal disturbance and interference in their day-to-day operations at the water treatment plant. A hydraulic hoist was positioned between the two aerators with simple, bolt-on connectors, enabling an efficient and cost-effective installation process.

Final Project Details

Committed to designing and building projects that deliver success to our customers and their stakeholders, our construction team completed building the aerator bridge and was able to have it inspected and certified for operation by December 13th, 2018.

The finished product eliminates the repetitive process that required operators to climb up and down one aerator at a time for inspection of the aerator operations. The interstitial bridge also provides a level, safe staging area for water sampling and any future maintenance operations that need to be performed.

With technical expertise and an innovative organizational structure, the Kiely Family of Companies provides customers with a unified business approach and a single point of contact for unparalleled accountability for project success. Our design-build services enable design and construction teams to strategize as one, delivering a wealth of customer benefits and providing a tailored solution optimized for cost, quality, and efficiency. Trust the Kiely Family of Companies with your next design-build project.